Carbon Flat Products

Our products offering include:

Non-Coated

Coated/Corrosion-Resistant

Pre-Painted

Non-Coated

Hot-Rolled

Hot‒rolled steel is used in construction and heavy manufacturing. It has exceptional strength, workability, and cost‒effectiveness.

Key Characteristics

Cost-Effective:

The simpler manufacturing process makes it more affordable than cold-rolled steel.

Enhanced Formability:

Heating the steel makes it more malleable.

Superior Durability:

The production process creates a material free from internal stresses.

Common Applications

- Structural Components

- Automotive Industry

- Pipes and Tubing

- Agricultural Machinery

Non-Coated

Cold-Rolled

Cold‒rolled steel is a premium steel product valued for its tighter tolerances and produces a smooth, often oily, surface that is free of scale.

Key Characteristics

Dimensional Accuracy:

Cold-rolled steel can be manufactured to precise dimensions and thicknesses with excellent consistency.

Increased Strength:

The strain hardening that occurs during the process can increase the steel's strength and hardness by up to 20%.

Enhanced Straightness:

Products made from cold-rolled steel are straighter and have more precise corners than their hot-rolled counterparts.

Common Applications

- Automotive Industry

- Appliances

- Metal Furniture

- Industrial & Electrical Components

Coated/Corrosion-Resistant

Galvanized Steel Coil

Galvanized coil steel is the primary form in which galvanized steel is produced and supplied for modern, high‒volume manufacturing.

Key Advantages

Superior Corrosion Protection:

The hot-dip galvanizing process provides a tough, bonded zinc coating that resists rust and corrosion.

Production Efficiency:

The coil format allows for continuous feeding into machinery, significantly reducing production time and waste.

Consistent Quality:

Coils are produced with uniform thickness, width, and coating, ensuring consistent performance.

Types & Uses

- HVAC Industry

- Construction & Roofing

- Appliance Manufacturing

- Automotive Components

Coated/Corrosion-Resistant

Galvalume

Galvalume is a technologically advanced steel sheet coated with a highly corrosion‒resistant alloy of aluminum and zinc. This combination provides a service life two to four times longer than traditional galvanized steel.

Key Advantages

Superior Corrosion Resistance:

The aluminum-zinc alloy offers exceptional protection against rust and the elements.

Heat Reflectivity:

The metallic surface reflects solar heat, helping to lower building cooling costs.

Lightweight Strength:

Offers excellent structural integrity without the bulk, making transport and installation easier.

Coated/Corrosion-Resistant

Galvanneal

Galvanneal is steel coated first by hot‒dip galvanizing (zinc) and then annealed, forming a zinc–iron alloy layer with enhanced properties.

Key Advantages

Excellent paint adhesion due to its matte gray alloy surface, ideal for coated applications.

Improved formability and weldability compared to regular galvanized steel, making it suitable for fabrication and assembly.

Harder, more durable coating than galvanized steel, reducing surface damage and improving scratch resistance.

Common Applications

Automotive body panels, HVAC components, electrical enclosures, and appliance housings.

Coated/Corrosion-Resistant

Aluminized Steel

Aluminized steel is carbon steel coated by dipping in molten aluminum or an aluminum–silicon alloy, making it a durable and heat‒resistant material.

Key Advantages

Outstanding corrosion resistance due to the aluminum coating.

High heat reflectivity and temperature tolerance, making it ideal for high-temperature environments.

Retains steel strength and formability, yet behaves like aluminum in thermal environments.

Pre-Painted Steel

Cold Rolled

Aluminized steel is carbon steel coated by dipping in molten aluminum or an aluminum–silicon alloy. The process produces a strong metallurgical bond, resulting in a durable and heat‒resistant material.

Key Advantages

Factory Finish: Consistent, high-quality paint application in many colors and textures.

Enhanced Durability: Multi-layer protection (steel + zinc/aluzinc + primer + paint).

Time & Cost Efficiency: No need for on-site painting, reducing labor and material costs.

Design Flexibility: Available in various gloss levels, matte finishes, and textures.

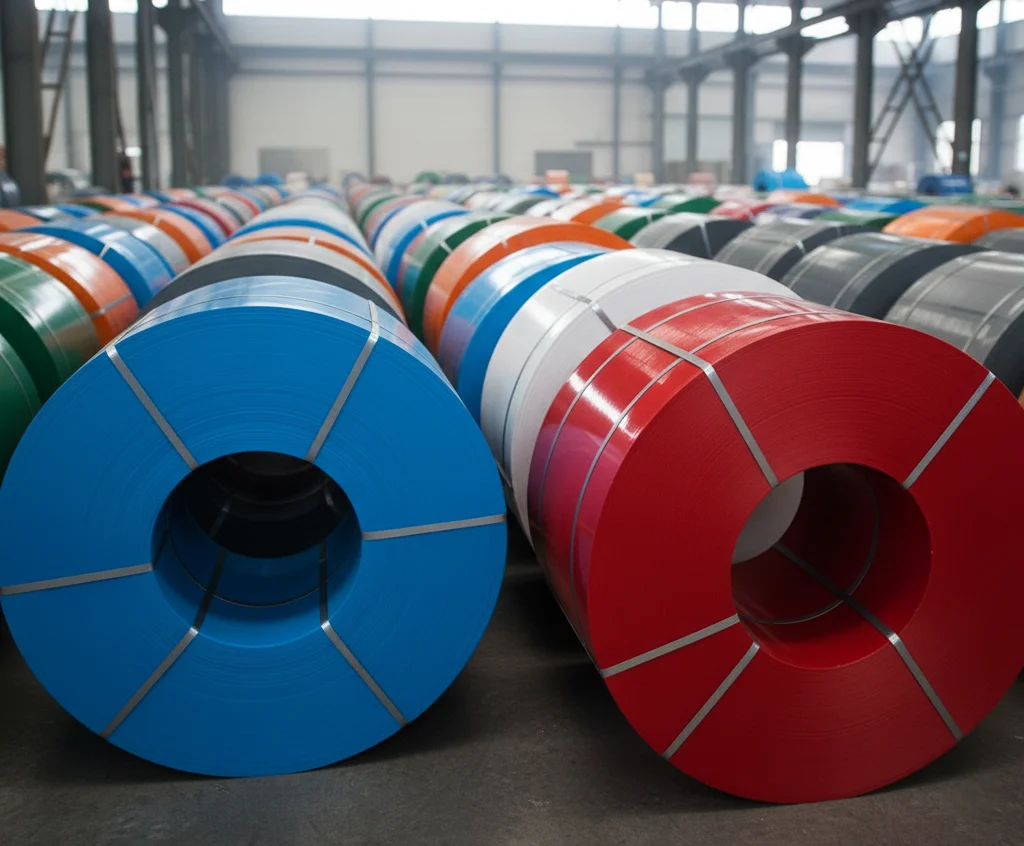

Pre-Painted Steel

Galvanized

Pre‒painted galvanized steel coil is made from galvanized steel (zinc‒coated) that is processed through a continuous coil‒coating line.

Key Advantages

Strong Corrosion Resistance: Combines zinc protection with factory-applied paint layers.

Wide Color Range: Available in many colors, finishes, and gloss levels for versatile design.

Cost-Effective: Delivers excellent performance and appearance at a competitive price.

Ready for Use: Saves time and labor by eliminating the need for on-site painting.

Pre-Painted Steel

Galvalume

Pre‒painted galvalume steel coil is made from galvalume steel that undergoes a continuous coil‒coating process with multiple layers of primer and paint. This combination provides the superior corrosion resistance of galvalume.

Key Advantages

Exceptional Durability: Multi-layer system (steel + aluminum-zinc coating + paint) ensures long-term resistance against rust, UV rays, and harsh climates.

Aesthetic Versatility: Available in a wide range of colors, gloss levels, and textures for design flexibility.

Cost & Time Efficiency: Delivered ready-to-use, eliminating the need for on-site painting.

Heat & Weather Resistance: Maintains structural integrity in high-temperature and marine environments.